Siemens X300 EV9-4 Echo Ultrasound Scanner Probe Endocavity Transducer

product detail

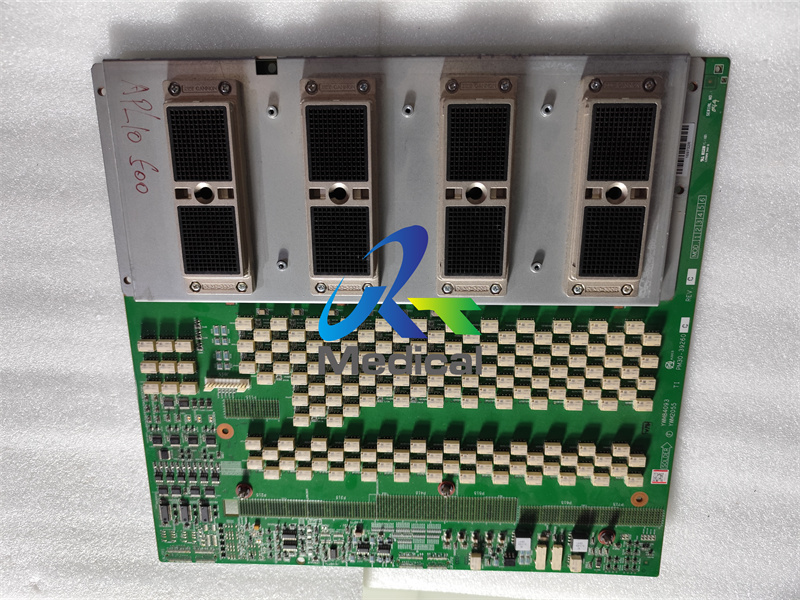

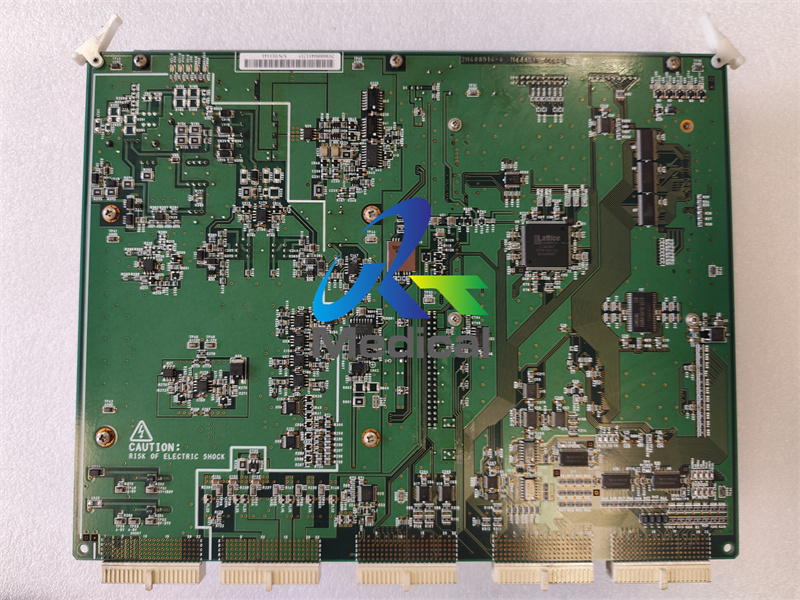

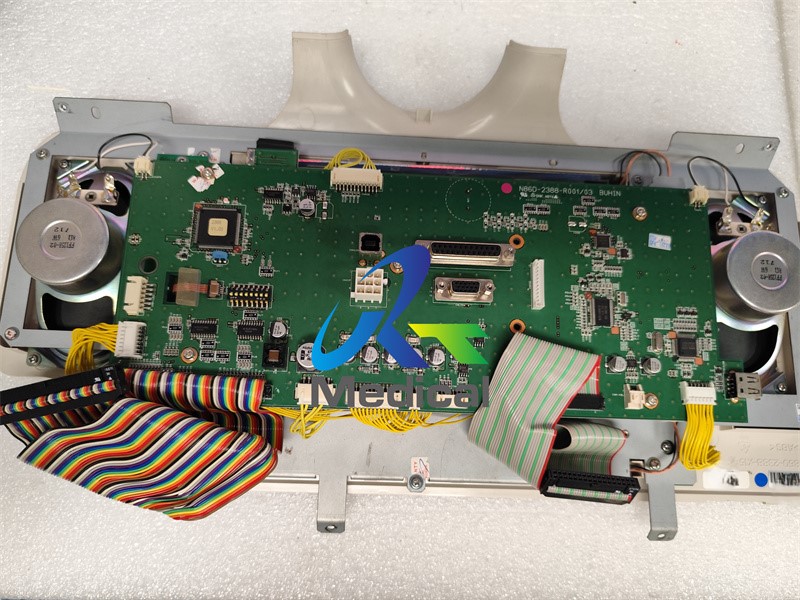

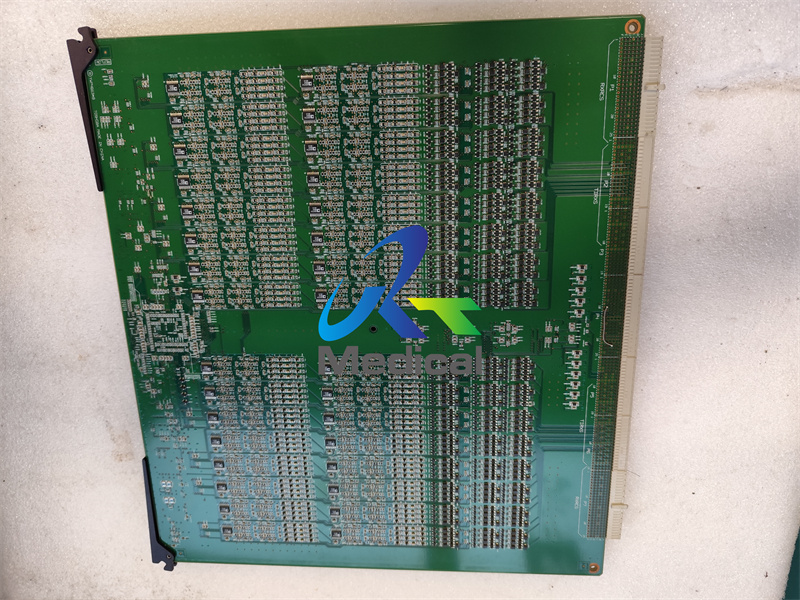

Structure of the transducer

The parameters of the transducer performance, which influence the quality of ultrasound images, are the axial and lateral resolution and sensitivity. The axial resolution is determined mostly by the frequency of the ultrasound wave. As the frequency increases, the wavelength decreases, which is advantageous because it provides a better distinction between a target and other objects. The lateral resolution along the direction orthogonal to the axial direction is determined by the beam profile of the transducer. A narrower beam leads to better resolution along the lateral direction. The sensitivity of the transducer determines the contrast ratio of the ultrasonic images. A transducer with higher sensitivity can generate a brighter image of the target. The transducer is designed to acquire high-quality images by enhancing these performance parameters.

A typical 1D array transducer is composed of an active layer, acoustic matching layers, a backing block, an acoustic lens, kerfs, a ground sheet (GRS), and a signal flexible printed circuit board (FPCB). The active layer is usually made of a piezoelectric material—mostly piezoceramic. The active layer generates an ultrasound wave in response to an electric driving signal, receives the wave reflected at the boundary of an organ, and converts the received ultrasound wave to an electric signal by means of the piezoelectric effect. However, the big difference in the acoustic impedance between piezoceramic elements and a human body prevents the efficient transfer of ultrasonic energy between the two media. The acoustic matching layers are used to facilitate the transfer of ultrasound energy. Each matching layer has a thickness of one-quarter wavelength at the center frequency of the transducer. The backing block is used to absorb the ultrasound wave propagating backward from the piezoelectric element. If the backward wave is reflected at the bottom of the backing block and returned to the piezoelectric element, it can cause noise in the ultrasound image. Thus, the backing block should have a high attenuation. In addition to this material damping, several structural variations have been implemented to increase the scattering effects inside the backing block, e.g., inserting grooves or rods in the block . The backing block commonly has an acoustic impedance between 3 and 5 Mrayl. If the backing block has an acoustic impedance that is too high, the acoustic energy generated by the piezoelectric element will be wasted by the backing block and few ultrasound waves will be transmitted to the human body. The acoustic lens protects the ultrasonic transducer from exterior damage, and focuses the ultrasound beam onto a specified point based on Snell’s law. Materials with low attenuation constants are preferred to reduce the loss of ultrasound energy inside the lens. Typical acoustic lenses are made of rubber materials for comfortable contact between the transducer and patients. The kerf is a gap between arrayed piezoelectric elements that isolates each element from its neighboring elements to reduce the crosstalk between them. The crosstalk seriously degrades the transducer performance. Therefore, various shapes and materials of the kerf have been developed to decrease the crosstalk .